Smart Scale InVision

Experience efficiency with Smart Scale InVision—a revolutionary weighing system integrating advanced algorithms, visual recognition, and image capture to transform picking and packing operations. Seamlessly connecting with production and ERP systems, it offers real-time visibility and proof of successful order fulfillment. Monitor and track processes effortlessly, ensuring accuracy and efficiency. InVision scales not only enhance accuracy but also boost productivity with guided working steps and intuitive process verification, leading to significant efficiency gains.

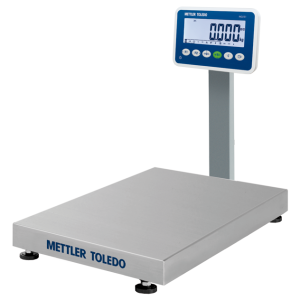

Unlock the full potential of your operations with productivity improvements of up to 30%. Equipped with a high-quality camera, user-friendly HMI, and precision platform, Smart Scale InVision is a complete solution. The smart machine-learning algorithm ensures accurate parts recognition, while the rugged design guarantees reliability in demanding environments. Enjoy seamless integration with SAP and other ERP or MES systems for comprehensive control and reporting.

| Housing type | Camera boom: AISI 304 Platter: ABS 757 |

| Dimensions (L x W x H) | Camera boom: 280 × 321.5 × 798.5 mm Platter: 435 × 310 × 46.5 mm Installed with PBD769-AB-15: 435 × 444 × 802 mm |

| Net weight | Camera boom: 5.9 kg Platter: 0.59 g |

| Power supply | 100–240 V AC, 50/60Hz, 0.15 A |

| Camera parameters | Model: acA4024-8gc Basler ace GigE camera Resolution (H x V pixels): 4024 x 3036 Sensor type: Sony IMX226CJL-C, progressive scan CMOS, rolling shutter Optical size: 1/1.7” Mono or color: Color Image data interface: Gigabit Ethernet (1000 Mbit/s) Synchronization: Via software trigger Exposure time control: <100,000 Camera power requirements:

|

| Lens working conditions | <55% relative humidity |

| Image parameters | 3020 x 2430 (H x V pixels, factory default) |

| Type of protection | The InVisionTM system satisfies the requirements for protection class IP20. |

| Operating temperature | 0 °C -/+35 °C (at 10–70% relative humidity, non-condensing) |

| Storage temperature | -20 °C -/+60 °C (at 10–70% relative humidity, non-condensing) |

| Ambient conditions according to EN 61010 | Indoor use only Pollution degree 2 Overvoltage category II Max. installation height 2,000 m AMSL |

| Recommended ambient lighting condition | Illuminance: 350–650 lux Coefficient of variation: <20% Color temperature: 4000–6500 k |

| Hazardous areas | The InVisionTM system cannot be operated in hazardous areas. |

| Communication (camera connectors) | Ethernet connector:

I/O connector:

|

| IND970 HMI display | 15” touchscreen: 1280 x 800 TFT LED backlight Membrane keypad: 38 keys with numeric keypads, navigation keys, function keys and scale-function keys |

| Application restrictions | The single part to be weighed and recognized through the InVisionTM system should be:

Scale specifications regarding platform dimensions and camera are currently available in only one configuration. |